As a thermal conductive filler,Aluminum nitride filler has high thermal conductivity and electrical insulation , add AlN ceramic microsphere into the resin or plastic can significantly improve the thermal conductivity.

The characteristics of AlN ceramic microsphere:

1. Spherical/Near-spherical

2. High filling volume

3. High liquidity

4. Narrow particle size distribution

5. High thermal conductivity

6. High insulation

Item No :

F-01/F-03/F-05/F-30/F-50/F-80/F-100/F-120/F-150Order(MOQ) :

1KGProduct Origin :

CHINAColor :

Gray-white

| Item | F-007 | F-03 | F-05 | F-30 |

| Mean particle size (μm) | 1.0~1.5 | 3~4 | 4~5 | 20~40 |

| Particle shape | Near Spherical | Near Spherical | Near Spherical | Spherical |

| Real density (g/cm3) | 3.26 | 3.26 | 3.26 | >3.30 |

| Thermal conductivity (W/m·K) | >170 | >170 | >170 | >170 |

| Bulk density (g/cm3) | 1.0~1.2 | 1.0-1.2 | 1.1~1.3 | 1.4~1.6 |

| Tap density (g/cm3) | 1.3~1.5 | 1.3-1.5 | 1.4~1.6 | 1.8~2.0 |

| Item | F-50 | F-80 | F-120 | F-150 |

| Mean particle size (μm) | 40~60 | 70~90 | 110~130 | 140~160 |

| Particle shape | Spherical | Spherical | Spherical | Spherical |

| Real density (g/cm3) | >3.30 | >3.30 | >3.30 | >3.30 |

| Thermal conductivity (W/m·K) | >170 | >170 | >170 | >170 |

| Bulk density (g/cm3) | 1.6~1.8 | 1.7~1.9 | 1.7~1.9 | 1.7~1.9 |

| Tap density (g/cm3) | 1.8~2.0 | 1.9~2.1 | 1.9~2.1 | 1.9~2.1 |

Application :

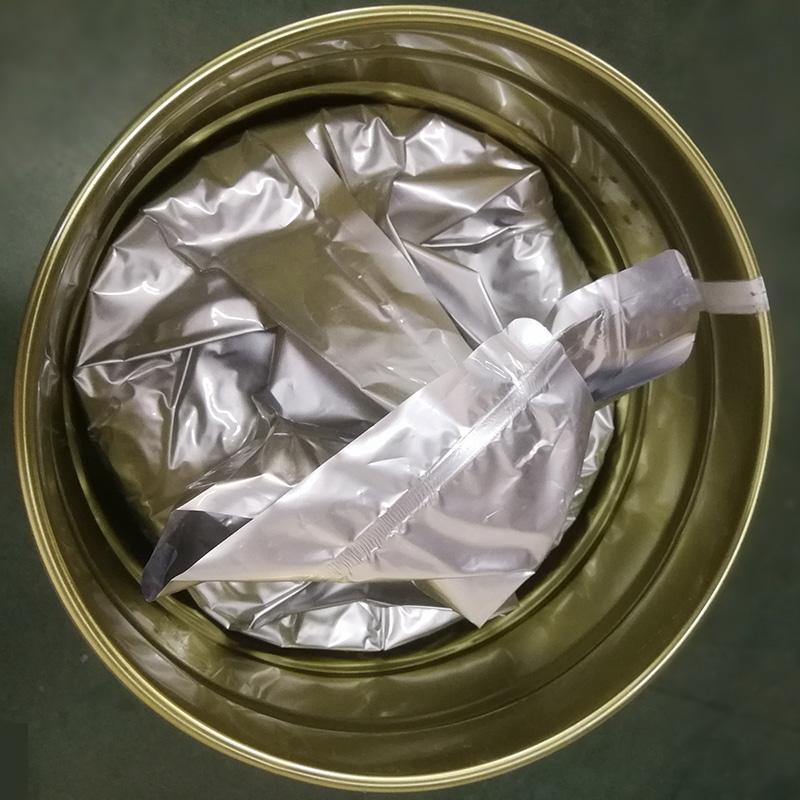

Package

10-20kg/bucket

aluminum nitride filler is packed in aluminum foil bags filled with nitrogen and then in iron drums.

Our advantage

Xiamen Juci Company has a plant area of 30,000 square meters, and the production workshop is equipped with 30 sets of single sintering furnaces, as well as 8 sets of advanced continuous sintering furnaces, with a production capacity of up to 1,000 tons/year of aluminum nitride powder. The testing center is about 800 square meters, equipped with more than 100 sets of professional powder and ceramics testing equipments such as scanning electron microscope, particle size meter, nitrogen-oxygen analyzer, powder comprehensive tester, thermal conductivity meter and so on. The company has a R&D center with an area of 1200 square meters, equipped with more than 40 sets of R&D special equipment, and a R&D team of more than 30 people who constantly promote product optimization and innovation, so that the company can maintain its competitive advantage in the fierce market competition.

Company Production Line

ISO Cetrificate

Tags :