Aluminum Nitride (AlN) thermal filler is a high-performance ceramic material widely used in thermal management applications due to its exceptional properties. Here’s a detailed breakdown of its functional roles:

1. Heat Dissipation (Primary Function)

High Thermal Conductivity (~170-200 W/mK) – Efficiently transfers heat away from hotspots in electronic components (e.g., CPUs, power modules, LEDs), making AlN powder ideal for high thermal conductivity fillers.

Reduces Thermal Resistance – Improves heat flow in composites (e.g., thermal interface materials (TIMs), epoxy resins), enhancing performance in electronic cooling solutions.

2. Electrical Insulation

Dielectric Strength (>15 kV/mm) – Prevents electrical short circuits while conducting heat, critical for high-voltage applications (e.g., power electronics, EV batteries), where AlN ceramic filler ensures reliability.

3. Thermal Expansion Matching

CTE (Coefficient of Thermal Expansion) ~4.5 ppm/K – Closely matches silicon and semiconductors, minimizing stress in bonded interfaces (e.g., chip packaging), making AlN single crystal filler a preferred choice for semiconductor thermal management.

By incorporating ultra-pure AlN filler or nanoscale AlN powder, manufacturers can optimize thermal conductivity while maintaining electrical insulation, making it a top choice for advanced thermal management ceramic materials.

Item No :

F-15Size :

15umOrder(MOQ) :

1KGProduct Origin :

CHINAColor :

Gray-white

| Item | F-15 |

| D50 (μm) | 13.0 |

| D90(um) | 20.0 |

| Particle shape | Near Spherical |

| Specific surface area (m2/g) | 0.3 |

| Bulk density (g/cm3) | 1.4 |

| Tap density (g/cm3) | 1.8 |

Application :

Thermal Interface Materials (TIMs): Greases, pads, adhesives for electronics cooling.

Encapsulation: Protects ICs/Power modules while dissipating heat.

Ceramic/Polymer Composites: Boosts thermal conductivity in PCB substrates, heat sinks.

LED & Laser Diode Cooling: Prevents lumen decay by managing junction temperatures.

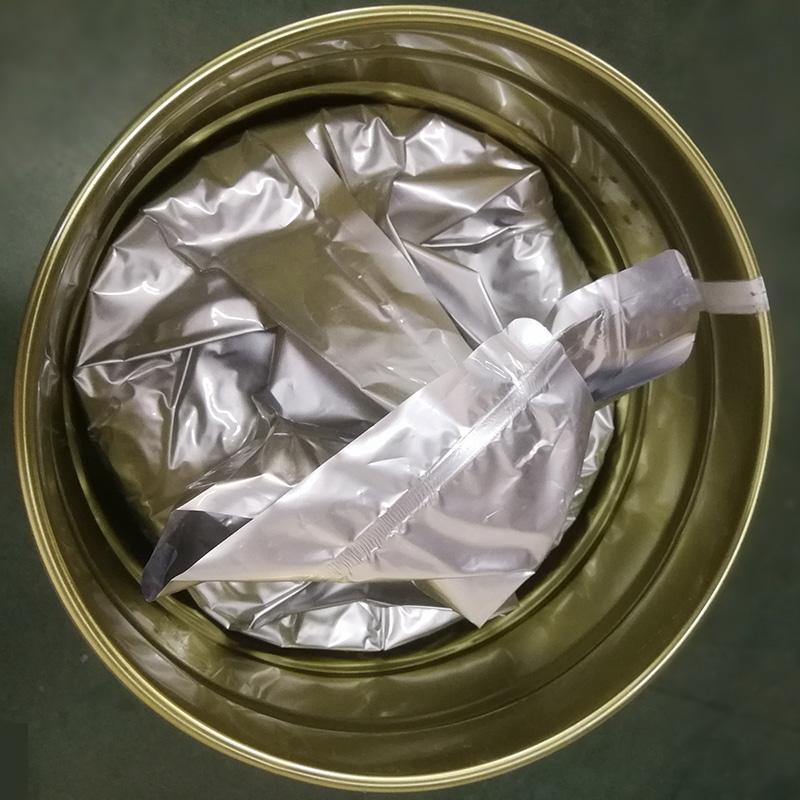

Package

10-20kg/bucket

aluminum nitride filler is packed in aluminum foil bags filled with nitrogen and then in iron drums.

Our advantage

Xiamen Juci is a professional manufacturer of aluminum nitride powder and ceramic products, with an annual production capacity of 700 tons of aluminum nitride powder. In its aluminum nitride filler powder product range, in addition to the existing polycrystalline spherical filler powder, the company has developed single crystal filler powders in sizes of 1um, 2um, 3um, 5um, 10um, and 15um, which are now in stable mass production. These powders can be applied in various thermal interface materials, such as thermal conductive silicone grease and thermal pads.

Company Production Line

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Tags :