30μm Aluminum Nitride (AlN) Ceramic Microspheres are high-performance inorganic non-metallic materials exhibiting outstanding thermal conductivity, electrical insulation, high-temperature resistance, and chemical stability. Their micron-scale spherical structure enables broad application prospects in advanced electronic packaging, composite reinforcement, thermal interface materials, and other fields.

Key Features of 30μm Aluminum Nitride (AlN) Ceramic Microspheres:

High Thermal Conductivity – With 170-200 W/(m·K) thermal conductivity, AlN microspheres significantly enhance heat dissipation in thermal interface materials (TIMs) and electronic packaging.

Excellent Electrical Insulation – Ultra-high resistivity (>10¹⁴ Ω·cm) makes these AlN fillers ideal for high-voltage applications, PCB substrates, and insulating coatings.

High-Temperature Resistance – Melting point of 2200°C ensures stability in extreme environments, suitable for aerospace, power electronics, and LED heat sinks.

Low CTE (4.5×10⁻⁶/°C) – Matches semiconductor materials (Si, GaN, SiC), reducing thermal stress in chip packaging and power modules.

High Purity & Chemical Stability – Corrosion-resistant and acid/alkali-proof, perfect for harsh industrial applications and chemical environments.

Uniform Spherical Structure – Narrow particle distribution (D50≈30μm) ensures superior flowability and even dispersion in polymers, composites, and 3D printing materials.

Item No :

F-30Size :

30μmOrder(MOQ) :

1KGProduct Origin :

CHINAColor :

Gray-white

| Item | F-30 |

| D50 (μm) | 30 |

| D90(um) | 50 |

| Particle shape | Spherical |

| Specific surface area (m2/g) | 3.31 |

| Bulk density (g/cm3) | 1.5 |

| Tap density (g/cm3) | 1.9 |

Application :

1. Electronics Encapsulation

High-thermal-conductivity AlN materials are widely used in IC packaging, LED heat sinks, and semiconductor substrates to enhance heat dissipation.

2. Thermal Interface Materials (TIMs)

Improves the thermal performance of thermal greases, thermal adhesives, and phase-change materials for efficient heat transfer in CPUs, GPUs, and power electronics.

3. Composite Reinforcement

Used in polymer-matrix composites (PMCs) and metal-matrix composites (MMCs) to boost mechanical strength and thermal conductivity for lightweight, high-performance components.

4. Aerospace & Defense

Ideal for high-temperature components, avionics cooling, and high-power electronics in extreme environments due to its thermal stability and low CTE.

5. 3D Printing Materials

Serves as a high-performance AlN powder for additive manufacturing, enabling precision ceramic 3D printing of complex, heat-resistant structures.

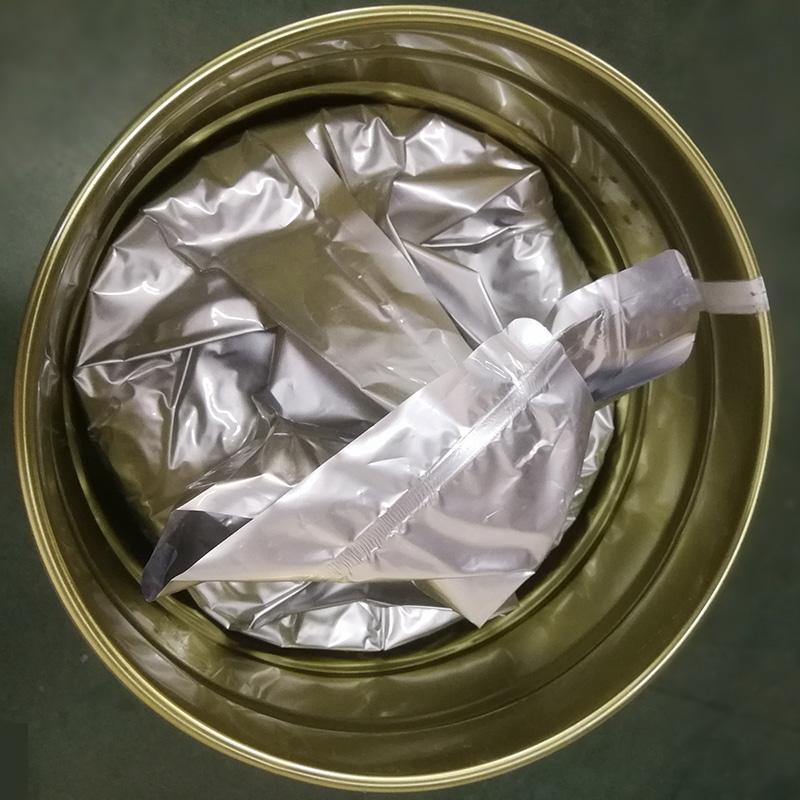

Package

10-20kg/bucket

aluminum nitride filler is packed in aluminum foil bags filled with nitrogen and then in iron drums.

The advantage of Xiamen Juci Technology Co., Ltd.

Large-Scale Production: One of the few mass-production AlN powder manufacturers in China, ensuring stable supply.

Precise Particle Size Control: Offers a full range of microspheres (30-150μm) with customizable particle size distribution.

End-to-End Capabilities: Provides one-stop solutions from powder synthesis to finished ceramic products.

Strict Quality Control: Purity ≥99%, meeting electronic-grade material standards.

Driven by technological innovation, JUCI Technology continues to support efficient thermal management solutions for 5G, new energy, and other cutting-edge industries.

Company and Laboratory

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Tags :