50μm aluminum nitride (AlN) ceramic microspheres are a high-performance thermal filler designed to enhance the thermal management properties of composite materials. With excellent thermal conductivity (~170-200 W/mK) and superior electrical insulation, AlN microspheres are an ideal choice for electronic packaging, thermally conductive adhesives, thermally conductive plastics, and high-power LED heat dissipation.

Key Features:

1、High Thermal Conductivity: Effectively improves heat transfer efficiency in composites, ideal for critical cooling applications.

2、Uniform Particle Size: 50μm microspheres ensure even dispersion, optimizing mechanical and thermal performance.

3、Electrical Insulation: High resistivity makes it suitable for insulation requirements in electronics.

4、High-Temperature & Oxidation Resistance: Exceptional stability for high-temperature environments.

5、Lightweight: Low density reduces overall product weight.

Item No :

F-50Size :

50μmOrder(MOQ) :

1KGProduct Origin :

CHINAColor :

Gray-white

| Item | F-50 |

| D50 (μm) | 50 |

| D90(um) | 80 |

| Particle shape | Spherical |

| Specific surface area (m2/g) | 3.31 |

| Bulk density (g/cm3) | 1.7 |

| Tap density (g/cm3) | 1.9 |

Application :

Thermal conductive silicone/epoxy resin filler

Heat dissipation fillers for high-power electronic components

LED substrates and packaging materials

5G communication device thermal management

Aerospace thermal composite materials.

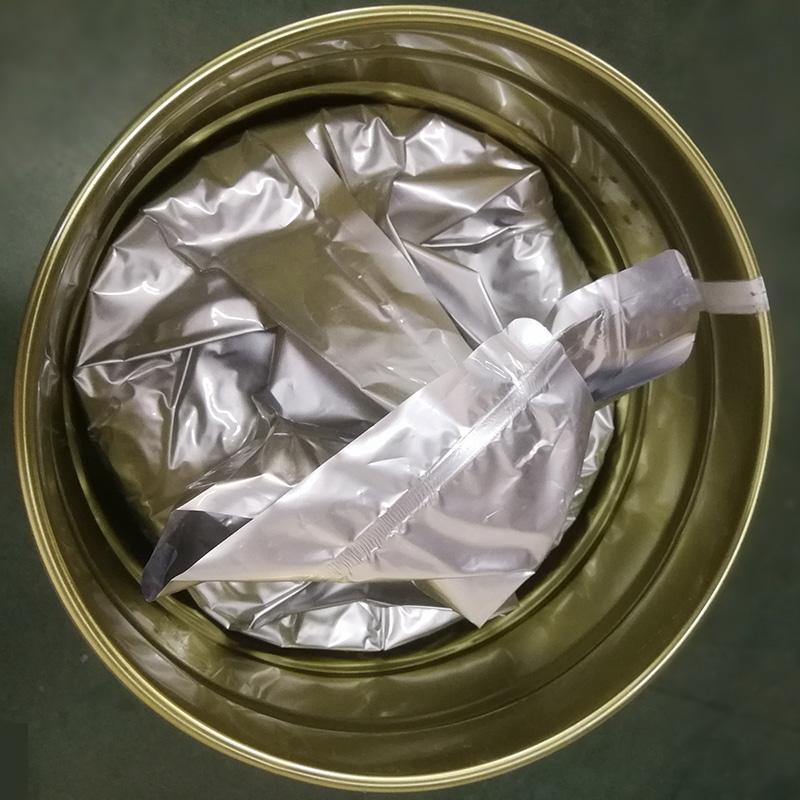

Package

10-20kg/bucket

Aluminum nitride filler is packed in aluminum foil bags filled with nitrogen and then in iron drums.

The advantages of Xiamen Juci Technology Co., Ltd.

Xiamen Juci Technology Co., Ltd. is the largest aluminum nitride (AlN) filler manufacturer in China.Xiamen Juci Technology's aluminum nitride (AlN) filler powder, with its high purity, superior thermal conductivity, and precision customization, empowers customers to break through thermal management bottlenecks.

①Utilizing high-purity raw materials (AlN purity ≥99%) to minimize impurities' impact on thermal performance.

②Exceptional thermal conductivity (170-200 W/(m·K)), far exceeding conventional alumina (~30 W/(m·K)) and approaching theoretical limits, significantly enhancing composite materials' heat dissipation efficiency.

③Offers a full range of particle sizes from nano-scale to hundreds of microns (e.g., 50μm), catering to diverse applications such as thermal adhesives, plastics, and ceramic substrates.

④Advanced spheroidization process ensures excellent particle dispersion, reducing internal porosity in composites and improving thermal uniformity.

⑤Provides surface-treated AlN powder (e.g., silane coupling agent modification) to enhance compatibility with resin, rubber, and other matrices, preventing filler agglomeration.

Company and Laboratory

Media Contact:

Xiamen Juci Technology Co., Ltd.

Phone: +86 592 7080230

Email: miki_huang@chinajuci.com

Website: www.jucialnglobal.com

Tags :